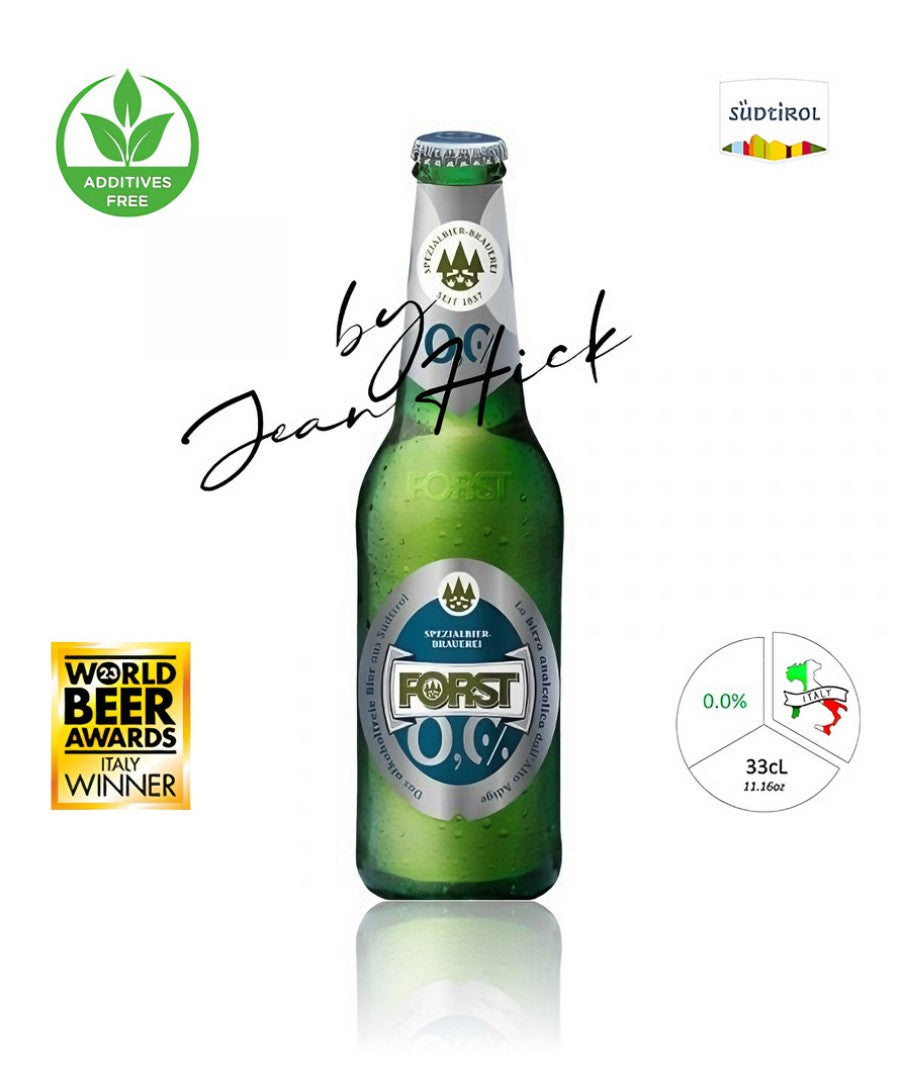

FORST 0.0% – ラガービール

FORST 0.0% – ラガービール

🍺 FORST 0.0% ラガー — ドロミーティ発、アルコールゼロの芸術 🏔️

南チロルの中心、オーストリアの伝統とイタリアの情熱が出会う地で生まれたFORST 0.0%ラガーは、本物の味を諦めたくない人のためのプレミアムな選択肢 🌟。

澄んだ黄金色、きめ細かく持続する泡、レモングラスのような香りと驚くほど豊かなコク 💛。

アルプスの清水、大麦麦芽、とうもろこしが織りなす、調和のとれた味わいと程よい辛口の余韻 ✨。

アルコールゼロ、低カロリーで等張性に優れ、アスリートの理想のパートナー 💪。

ドロミーティでのスキー後や爽やかな休憩時に、味と健康を両立する賢い一杯 🎯。

南チロル産、チャンピオンが認めた逸品 🏆!

受取状況を読み込めませんでした

折りたたみ可能なコンテンツ

原材料・栄養成分・ボトル仕様

原材料名:

水、大麦麦芽、トウモロコシグリッツ、ホップ、ビール由来の天然香料

アレルゲン: グルテン(大麦麦芽由来)

栄養成分(100mlあたり):

エネルギー:73kJ / 17kcal

脂質:0g

> 飽和脂肪酸:0g

炭水化物:4.1g

> 糖質:0.5g

たんぱく質:<0.5g

食塩相当量:<0.01g

遺伝子組換え原料不使用

アルコール分:0.0%

プラトー度:4.4%(脱アルコール前)

容器仕様:

内容量:0.33L

サイズ(幅×高さ):6 × 22.5cm

容器:濃緑色ガラス瓶

栓:王冠キャップ

保存方法: 直射日光や異臭源を避け、涼しく乾燥した場所で保管。

使用方法: よく冷やして提供し、開栓前に振らないこと。

料理との相性とテイスティング提案

🍽️ FORST 0.0% ラガーに合う料理

🥗 上質な前菜

タンポポとヤギチーズ、ローストナッツのサラダ 🥬🧀🌰

全粒粉トーストと燻製サーモン 🍞🐟

🧀 軽めの料理とチーズ

ハーブを添えた南チロル産フレッシュチーズ 🧀🌿

ローズマリー風味のローストポテト 🥔✨

🍗 メイン料理

有機鶏むね肉のグリル アップルとタイムソース 🍗🍏

アルプス産マスのレモンソース添え 🐟🍋

🍰 デザート

シナモンアップルタルトとバニラクリーム 🍎🌼

ベリー入りダークチョコムース 🍫🍓

📌 テイスティングポイント: 4〜6℃.で提供すると、モルトの旨みと爽快さが最も引き立ちます。

官能プロファイル

👁️ 外観

澄んだ黄金色 ✨、きめ細かくクリーミーな白い泡が長く続く 🫧 — アルプスの清水を思わせる。

👃 香り

穏やかな麦芽、山のハーブ、レモングラスの爽やかな香り 🍋🌿 が広がる。

👅 味わい

中程度のボディで、軽やかな飲み口。麦芽のほのかな甘みとバランスのとれた辛口の後味 🌾。細かな泡が舌をくすぐる。

✨ 余韻

清らかでドライ、香ばしい穀物と繊細なハーブがやさしく残る 🌿。

🌡️ 理想的な提供温度:4〜6℃. ❄️

4℃.未満 :複雑な香りが失われ、平板な印象に 🌬️

6℃.超 :爽快感が減り、麦芽の甘みが前面に出る 🥱

受賞歴とメダル

2023 - At the World Beer Awards (WBA), London, UK, Forst 0,0% wins the Gold Medal as the World's Best Beer in the No & Low Alcohol Lager category. The WBAs are the global awards that select the best of all internationally recognised styles, reward and promote the world's best beers to consumers and industry professionals worldwide.

製造工程と脱アルコール方法

The malt provided by the raw materials is stored in large silos. Afterwards, the portion required for a process known as " brewing " is ground and mixed in the brewing vat with water from the Marlinger mountain springs until the 'brew' is obtained. The wort is conveyed into the brewing cauldron where the hops are added and boiled for about an hour. This is how the complete and perfect fusion of 3 raw materials so different from each other takes place in the brewing room: a liquid (water), a grain (the barley malt), a flower (the hops). After the hops have been added and the wort boiled, the substances coagulated in the process are separated in a special tank, the Whirlpool. The wort is cooled and then brewer's yeast is added to the fermentation tank, which converts the sugary substances into alcohol and carbon dioxide. After the primary fermentation phase, the yeast is removed from what can for the first time be called " beer ", or rather " young beer ". The fermentation process lasts 7-8 days at a controlled temperature. But this 'young beer' still has to mature in order to fully express its extraordinary flavour.

The long maturation phase, which requires very low temperatures (< 0°c), takes place in our maturation cellars, under the watchful eye of the master brewers. With the natural elimination of those compounds that characterise its 'sourness', the beer goes from 'young' to 'mature', and is then filtered and finally sent for packaging.

The result is a fresh, thirst-quenching FORST beer ! !

製造者とブランドの歴史

FORST beer was born in 1857 in the hamlet of Foresta in the municipality of Lagundo (Algund, on the outskirts of Merano), from the happy intuition of Johann Wallnöfer and Franz Tappeiner from Merano. This place immediately provided the best conditions for brewing beer: superlative water gushing from the springs of the San Giuseppe-Josefsberg and Marlengo mountains (1793 m), the possibility of storing natural ice during the winter, necessary to cool the cellars dug out of the rocks in the summer, and a convenient road for transit. Josef Fuchs (a farmer who owned a post office), the progenitor of the family that still owns the shares today, took it over, with the support of his wife Filomena, in 1863 with a production of just 230 hectolitres per year and had the first Forst brewery plant built where it still stands today. Taking advantage of his entrepreneurial streak, he also managed to exploit the grains resulting from beer production as fodder for livestock, being the owner of a farm with an adjoining livestock farm. Josef died in 1892 and two years earlier, in 1890, he handed over management to his son Hans, who increased production first to 8,900 hectolitres, and then to 22,500 in 1901. In that year, Forst was equipped with Linde refrigeration compressors for cooling the cellars and making ice. Production thus grew to 64,000 hectolitres annually on the eve (1913) of the Great War. However, the advent of the war also affected this brewery, which saw production drop to around 10,000 hectolitres in 1917. That same year, Hans died and his widow Fanny took over the reins of the business until 1933. In 1921, production reached 43,000 hectolitres. In 1933, Fanny left the management to her son Luis ("Alois") Fuchs, an engineer, who would run it for 56 years. The 1930s also saw Forst endeavouring to eliminate competitors operating in the vicinity, so that the Blumau breweries in Vilpiano (later sold to Dreher), the Mafei brewery in Rovereto and the Trentina brewery in Castelfondo were taken over in this order. In 1948 Forst concluded a contract with the Sicilian brothers Andrea and Francesco Vesco securing the exclusive right for the Centro Imbottigliamento Siciliano Prodotti Alimentari (CISPA) in Palermo to bottle and supply Forst beer throughout Sicily. In 1955 the Seeber Brewery in Sterzing, founded by Peter Seeber in 1875, was taken over. He himself changed the name to Società Anonima Ditta Seeber in 1939, and as can be deduced from a famous label showing a drinker wearing a colonial helmet, and as was the case for other breweries in the fascist period, began exporting to Africa. After its absorption by Forst, it continued to produce until 1969. Since 1991, Forst has also been the owner of the Menabrea Brewery in Biella (a company that was in great financial difficulty). In this case, with much foresight, it was decided to let this brewery operate with maximum autonomy. A decision that was rewarded by the great recognition it received worldwide. In 2010, Margarethe Fuchs, Baroness Von Mannstein (Innsbruck 1918-Merano 2015), who had inherited Forst on the death of Luis in 1989, passed the hand over to her daughter Margherita Fuchs (who was made a Knight of Labour by the President of the Italian Republic Sergio Mattarella in 2022). In 2011, a large new baking hall (the fifth, with a special low- pressure baking system) designed by Stahlbau Pichler of Bolzano was inaugurated. And over the years, Forst has developed into one of the leading breweries in Italy. To this day, it is the only family- owned Italian brewery. Current production stands at around 900,000 hectolitres per year and today, Forst has chosen diaphragm valves, separators and pressure gauges from ASV Stubbe for its plant, which guarantee maximum reliability and excellent results. ASV Stubbe products are used in the wort brewing room within the CIP sanitisation plant. After more than 166 years, the company is still located in the same place on both sides of the old imperial road from Merano to the Vinschgau.

Generation after generation, the company has evolved into one of the most important family-run independent businesses in the brewing industry, producing high quality beer specialities. Today, Margherita Fuchs von Mannstein, together with her daughters, the fifth generation of the family, continues to follow and carry on the company's vision: a purist approach to the art of brewing, high product quality with full respect for nature, proximity and a long-term relationship of loyalty with customers as well as strong social responsibility and a strong connection to the region form the basis of the commitment of a company with deep local roots.

A company of national importance, Forst stands behind Birra Castello. The brewery, undoubtedly the most beautiful in Italy (structures decorated with paintings and wooden balconies that give the idea of a medieval village), has state-of-the-art technology. Recently, a new structure was built with an energy recovery system that ensures maximum efficiency in the use of thermal energy. Attached to the brewery, a beautiful taproom, the Bräustüberl, with traditional, carefully prepared cuisine, is the meeting point for loyal local fans of Forst products, which are served raw on tap. In summer, a pleasant Bräugarten opens, cooled by the shade of the trees.

認証

2012 - Milano Finanza (Italian National Daily Business newspaper), in collaboration with Pwc (Price Waterhouse Coopers) has elected Forst as a champion of excellence in the beverage sector, delivering the 2012 Innovation Award Certificate.

2010 - Award for the centuries-old membership in the General Confederation of Italian Industry (Confindustria) as a certificate of loyalty. The Forst Brewery has been a member of Confindustria since its foundation on 5 May 1910 in Turin, Italy. The only company in Trentino-Alto Adige/South Tyrol to be awarded a diploma for 100 years of membership.

Since 2000 - Member of the International Slow Food Organization.